Ready to get started?

Axolt delivers Salesforce-native ERP and asset lifecycle solutions for Manufacturing and Asset Services organisations transitioning to service-led, lifecycle-driven operating models.

All natively on Salesforce.

(Why Lifecycle Thinking Is Replacing Functional Silos in Manufacturing and Asset Services)

For decades, asset-driven businesses were organised around a simple boundary:

Manufacturing builds the asset.

Service maintains it.

What happens in between, and after, was treated as someone else’s problem.

That operating model no longer works.

In Manufacturing and Asset Services, value is no longer created at the moment an asset leaves the factory. It is created, or destroyed, across the full lifecycle:

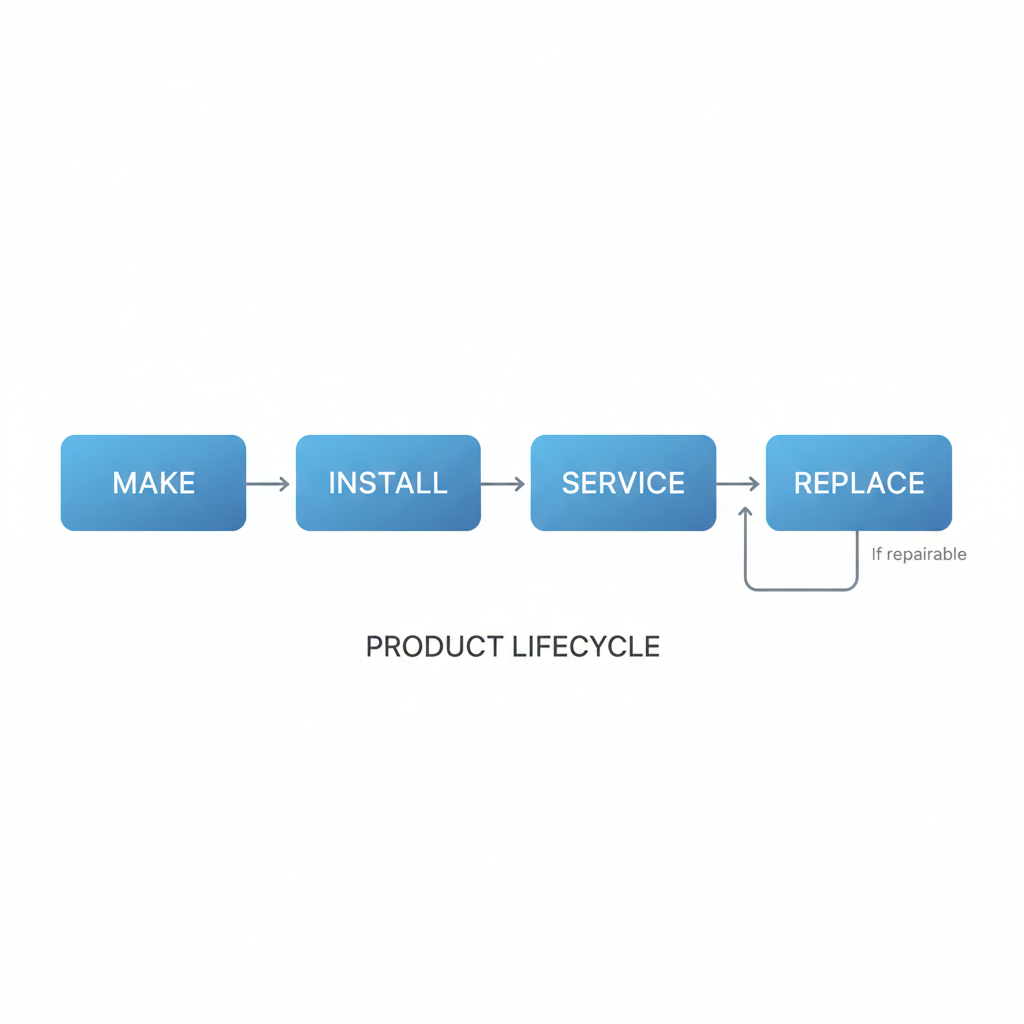

Make → Install → Service → Replace

This article explores why asset-driven businesses are shifting to lifecycle-centric operating models, how disconnected systems cause revenue leakage and blind spots, and why a unified data model is foundational for predictive, service-led growth.

The New Reality: Assets Are Long-Lived Value Engines

Modern asset-driven businesses depend on:

In many industries, lifetime service revenue exceeds the original asset sale.

Yet most systems still treat service as an afterthought.

This mismatch is why operating models are changing.

The New Reality: Assets Are Long-Lived Value Engines

Modern asset-driven businesses depend on:

In many industries, lifetime service revenue exceeds the original asset sale.

Yet most systems still treat service as an afterthought.

This mismatch is why operating models are changing.

Manufacturing knows:

But this data often stops at shipment.

Installation adds:

This information is rarely fed back into manufacturing insight.

Service generates:

But this intelligence often lives outside ERP.

Replacement decisions depend on:

Without lifecycle data, replacement is guesswork.

When these stages are disconnected, the asset’s story is broken.

Lifecycle thinking is not a mindset problem.

It is a data problem.

A unified data model means:

This allows:

Without a unified model, lifecycle insight is reconstructed, late and imperfectly.

Service revenue looks healthy on paper.

In reality, many organisations leak value through:

Why?

Because service contracts, assets, and financials live in different systems.

Common symptoms:

This is not a service execution problem.

It is a data continuity problem.

Service teams often lack:

So they default to:

Each action feels safe.

Collectively, they erode margin.

Lifecycle visibility turns service from a cost centre into a controlled revenue engine.

Everyone talks about predictive maintenance.

Few are ready for it.

Predictive maintenance does not start with algorithms.

It starts with:

If service data is fragmented:

Predictive maintenance is not an add-on.

It is the outcome of a connected lifecycle operating model.

Silos exist because systems enforce them.

Manufacturing ERP

Service Management

Asset Registers

Finance Systems

Each answers a different question.

None answers:

“What is the full economic and operational story of this asset?”

Lifecycle thinking requires:

Without that, organisations debate whose data is “right” instead of acting.

Lifecycle models collapse when:

A platform with:

…allows lifecycle insight to be native, not engineered.

This is where Salesforce-native architectures change what’s possible.

When manufacturing, service, and finance run natively on Salesforce:

The asset stops being “handed off”.

It becomes continuously understood.

Asset-driven leaders are reorganising around:

This requires:

Manufacturing and service are no longer separate businesses.

They are two phases of the same value stream.

The biggest shift in asset-driven businesses is philosophical:

The factory floor is not the finish line.

Value is realised:

Businesses that adopt lifecycle operating models don’t just service assets better.

They understand them better.

And understanding compounds.

Axolt delivers Salesforce-native ERP and asset lifecycle solutions for Manufacturing and Asset Services organisations transitioning to service-led, lifecycle-driven operating models.

All natively on Salesforce.

Adding {{itemName}} to cart

Added {{itemName}} to cart