Available on Salesforce AppExchange

Axolt Learn how Axolt extends Salesforce into end-to-end ERP

Explore Axolt on AppExchange

No manufacturer plans for a recall.

They plan to prevent one.

They invest in quality systems, audits, SOPs, and controls and assume that if a recall ever happens, the organisation will “figure it out”.

That assumption is where most recalls go wrong.

In Pharma, MedTech, and Cosmetics, recalls don’t fail because teams don’t care.

They fail because systems that work in calm conditions collapse under pressure.

This article walks through a realistic recall scenario hour by hour and exposes where data gaps, manual processes, and disconnected systems turn a contained issue into a regulatory, financial, and reputational crisis.

It starts quietly.

A quality manager receives an internal deviation report:

• A stability result outside trend

• A complaint referencing an adverse reaction

• A supplier notification about potential contamination

At this point, nothing is confirmed.

But the clock has started.

In regulated industries, time is not neutral.

Every hour without clarity increases exposure.

Leadership asks a simple question:

“Which products could be affected?”

This is where systems are tested.

Not theoretically.

Not in training.

In reality.

To answer this, teams must know:

• Which batches used the material

• Which lots were produced

• Which serials (if applicable) were released

• Which products are still in inventory

• Which have already shipped

If this requires:

• Multiple spreadsheets

• Cross-team calls

• Manual data stitching

You are already behind.

As the recall scope expands, stress reveals gaps no audit ever exposed.

Common failure points

• Batch genealogy exists — but not downstream shipment linkage

• Inventory data is current — but quality status is not

• ERP shows shipments — CRM shows customers — but nothing ties them together

• Serialisation data exists — but only at manufacturing, not service

Teams start asking:

• “Is this the latest file?”

• “Who owns this data?”

• “Can we trust these numbers?”

Under pressure, uncertainty multiplies.

Day 1: Regulatory Reporting Stress Begins

In Pharma and MedTech, regulators don’t wait.

Authorities such as the U.S. Food and Drug Administration expect:

But regulatory reporting requires:

If systems are disconnected, reporting becomes:

Every update risks contradiction.

And contradictions destroy credibility.

Day 2–3: Forward Traceability Becomes the Bottleneck

Backward traceability is usually manageable:

“What went into this batch?”

Forward traceability is where recalls slow down:

“Where did everything go — and who is affected?”

This includes:

In Cosmetics, this may mean retail chains and e-commerce platforms.

In MedTech, it may mean implanted devices.

If forward traceability is incomplete:

Both outcomes are costly.

Day 3–5: Financial Reality Sets In

By now, finance is involved.

And the questions change.

Without real-time linkage between:

Finance works with estimates.

Estimates become disclosures.

Disclosures become risk.

In most recall failures, systems break in predictable ways:

• Manufacturing knows batches

• Quality knows deviations

• Supply chain knows shipments

• CRM knows customers

• Finance knows numbers

But no one system knows the full story.

The recall becomes a coordination exercise instead of an execution exercise.

And coordination is slow under pressure.

Recall-ready organisations don’t rely on memory or manual work.

They rely on:

• A single source of operational truth

• End-to-end traceability by design

• Real-time status visibility

• Enforced workflows

This allows teams to:

• Define scope confidently

• Act decisively

• Communicate clearly

• Report defensibly

Speed becomes a capability, not a gamble.

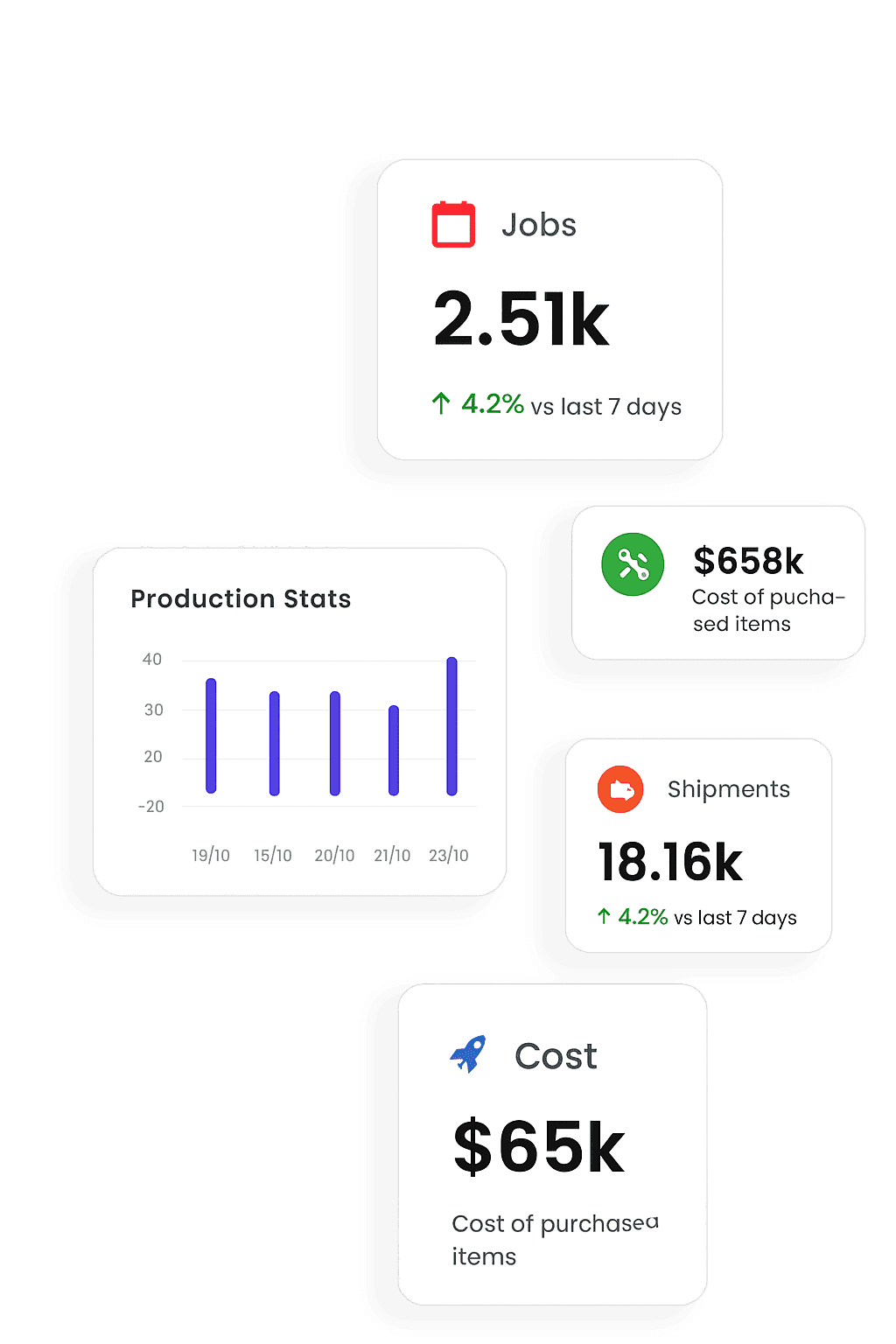

In Salesforce-native ERP architectures:

• Manufacturing, inventory, quality,

CRM, and finance share one data model

• Batch, lot, serial, and shipment data are linked natively

• Audit trails are automatic

• Reporting is consistent across functions

This reduces recall execution from:

“Let’s figure this out”

to:

“Here is the impact — now let’s act”

In regulated environments, that difference is everything.

In a recall, people do their best.

Systems decide the outcome.

If your systems:

• Fragment data

• Delay truth

• Depend on manual effort

They will fail you at the worst possible moment.

The recall you never planned for is not hypothetical.

It is a scenario every regulated

manufacturer should model — honestly, under pressure, without assumptions.

Because when it happens, there is no time to redesign systems.

Only to reveal them.

Axolt helps organisations:

• Build true end-to-end traceability

• Eliminate recall data gaps

• Accelerate regulatory reporting

• Reduce financial and reputational exposure

All natively on Salesforce.

Axolt Learn how Axolt extends Salesforce into end-to-end ERP

Explore Axolt on AppExchange

ERP

user/month

CPQ

Supply Chain & Logistics

Manufacturing

Finance

HRMS

Booking & Scheduling

Adding {{itemName}} to cart

Added {{itemName}} to cart