Ready to Learn More?

Visit our AppExchange listings:

Axolt ERP Suite

Axolt Logistixs – Inventory, Shipping & Warehouse

Axolt Manufacturing Suite

Reach out directly via LinkedIn or email

support@axolt.com

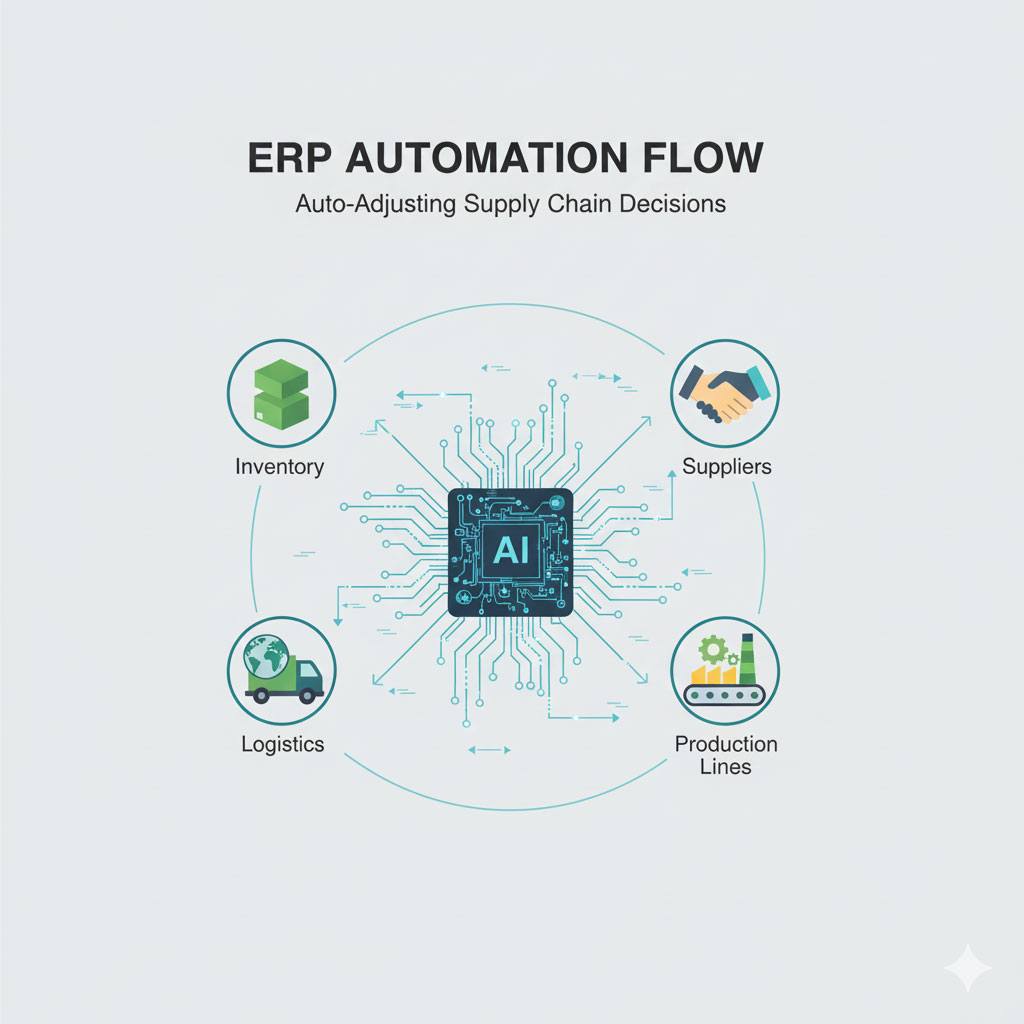

Axolt ERP

Built on Salesforce. Designed for real-world operations. Ready to grow with you.